What's pultrusion?|pultrusion process

23/11/2022

23/11/2022What's pultrusion?

1.FRP pultrusion: the reinforcement materials used in pultrusion process are mainly glass fiber and its products, such as roving, glass fiber felt, etc. In order to meet the special performance requirements of products, we can use glass fiber,carbon fiberlbasalt fiber can be used.

2.Pultrusion method belongs to a kinds of forming thermal curing composite materials.The profile will continuously comes out from the molds and it’s continuous production process. The direct-roving pass the resin and then squeezed into the molds with pultrusion machinery,hydraulic machine or the caterpillar machine.And the resin heated and then curing in the mold and comes out,in the last. The cutter will cut the profile at the fixed length.

We can roughly see the process into 2 simple steps.

1. Then the next section of impregnated fibers is pulled out and then the fibers are solidified and shaped in the hot mold, and then the mold is pulled out. Its main characteristics is the molding material is heated and cured in the mold, the curing time is setting, but the production efficiency is much higher than the hand-made profile and the quality control is easier among the composite material forming production with good surface performance.

2.The profile will be cutted at the fixed length and then sent to CNC to do the finial machining.

what's the different between the fiberglass pultrusion and carbon glass pultrusion?

● Carbon fiber composite pultruded material is widely used that is from military industry or civil use,which have many application.

● The carbon fiber is separated into 1K, 3k, 6K, 12K, 24K, 48K, 60K and 80K. K= 1000 For example: 40K= 40000 micro fibers in bond.

● The carbon pultrusion process is different from the common fiberglass pultrusion technology.

● The main different is at the carbon creels and resin tanks and preform design and sometimes,we will add after curing box to avoid the profile crack.

● The carbon creel:The carbon fiber need to go into the mold in parallel and every tension need to be same.

Raw materials for pultrusion process?

Direct Roving

E-glass: It is the most widely used in the pultrusion technology. It has good electrical insulation and mechanical characteristic.And the disadvantage is not suitable for use in acid environment.

C-glass:The advantage is the acid resistance is better than E-glass, but electrical performance, mechanical strength is only 10% - 20% lower than E-glass. Generally,most pultrusion profile don’t use this kind of glass.

In General:Roving for the pultrusion is used to make all kinds of the same cross-section complex profiles,the pultrusion product can make the strength much higher in the uni-directional.

Resin

The most common pultrusion resin below:

Unsaturated polyester resin

Vinyl ester resin

Phenolic resin

Epoxy resin

methacrylic acid and other resins

Our Brand Haoli Pultruion

● Nanjing Haoli Hydraulic machine Co., Ltd. is a technology-based production-oriented enterprise, established in 1999. Mainly engaged in the development, design and manufacture of hydraulic system, hydraulic transmission and control system and centralized oil supply and lubrication system.

● In 2000, it first entered the field of composite materials. It is the first enterprise that digests and absorbs the FRP pultrusion technology imported from abroad for the domestic related institutes, and provides its own FRP machine pultrusion unit.

● Our company has transferred FRP profile pultrusion technology to many enterprises.

● In recent years, with the in-depth development of composite industry in China, the company has developed a series of FRP pultrusion products to meet the needs of the development of FRP materials.

● At present, the company has provided a large number of FRP machine pultrusion production lines to customers.

● It has been proved that our products have high reliability and are more suitable for the needs of pultrusion technology in China.

● The products are exported to the Middle East and Europe.

● The company is a member of China composite materials.

● Our company has passed ISO9001 quality system certification in 2007.

● Nanjing, a manufacturer of pultrusion machine, has attracted a large number of young and middle-aged experts with rich technology and experience.

● The company's products are renowned in the industry for their expert quality and expert service.

● Nanjing Haoli, a pultrusion machine manufacturer, always adheres to the development strategy of integration of production, learning and research, takes product innovation as its own responsibility, and cooperates with universities and research institutes to tackle key issues.

● It is the industrialization transformation base of scientific and technological achievements in many universities.

● It has rapidly developed into a new high-tech enterprise with series products and large-scale production.

● At present, the company has a number of patents and software copyright, and has been recognized by high-tech enterprises in Jiangsu Province. Participate in the formulation of the industry standard of fiber reinforced composite hydraulic pultrusion machine.

● The machine is serialized, modularized and intelligent to meet the personal customization of customers' individual needs.

● The company always adheres to the excellent after-sales service work, carries out "turnkey" engineering service for customers, and creates a perfect pre-sales, sales and after-sales service system for customers.

● It starts with customer demand and ends with customer satisfaction. It's our duty to do our best in every aspect.

● Nanjing Haoli takes industrial rejuvenation as its own duty, adheres to scientific development and effective management, and is making great strides towards a newer and higher development goal.

What's the kind of pultrusion machinery?

Servo hydraulic traction pultrusion machine

1. Low noise, 50% energy saving compared with traditional hydraulic pultrusion machine;

2. Simple operation: the clamping force, traction force and pultrusion speed are set digitally;

3. Real time data recording in pultrusion process is convenient for quality control and technical management.

4.Temp.Control :Smart gauge and solid state relay

5.Driving Type :Servo Hydraulic

6.Control System :Touch screen and PLC

Hydraulic traction pultrusion machine

1. The fixture is easy to replace, suitable for pulling various glass fiber and carbon fiber profiles;

2. Convenient adjustment of traction, clamping force and pultrusion speed. It can realize stepless voltage regulation and speed regulation;

3. Linear guide rail is adopted for stable operation with centralized lubrication system.

Options:

1. Relay or PLC

2. Electric lifting of heating platform

3. Photoelectric coding speed measuring system

4. Upper or lower clamping

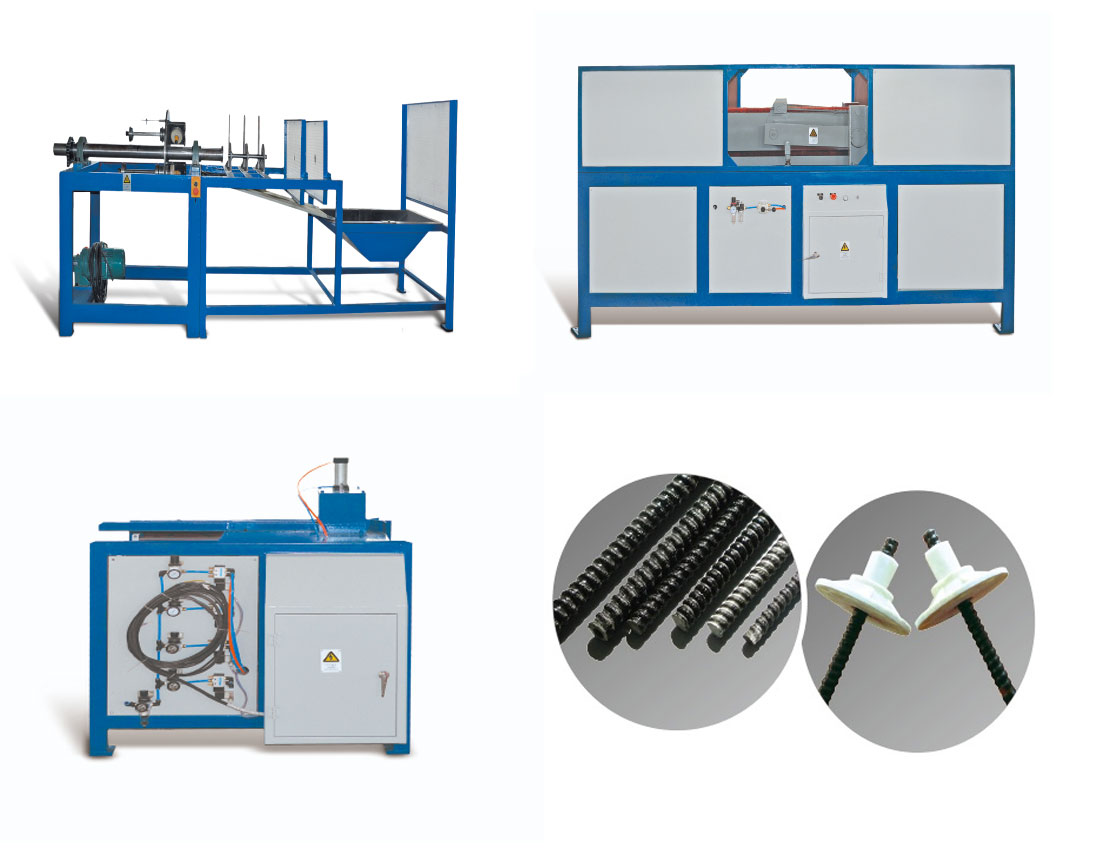

Crawler traction pultrusion machine

1. Suitable for producing small and medium sized FRP products;

2. The pultrusion speed is stable and the low speed is stable;

3. Hydraulic automatic clamping;

4. Low power consumption.

5.Clamp Length 1.5m

High strength FRP screw rod forming machine

The unit can produce left-hand or right-hand threaded rod with diameter of Φ 8 ~ Φ 40mm. The drying channel of the unit can be pneumatically lifted and equipped with unwinding machine. The machine is mainly suitable for the full screw rod machine with glass fiber as reinforcement material, polyester resin as matrix and pultrusion and winding.

Advantages of FRP threaded rod:

1. Good corrosion resistance;

2. Light weight and high strength;

3. The machine can be used to cut directly without sparks, so the disassembly work is avoided;

4. FRP full screw rod is widely used in mine roadway, railway tunnel, foundation pit and slope, military engineering and other anchor protection;

Note: the products produced by this machine can meet the above requirements.

Cutter machine

1. The cutting machine is mainly composed of three parts: bilateral hydraulic clamping device, movable cutting machine saw blade head, electrical control and measuring device.

2. As the continuous on-line production of pultrusion profiles, the cutting machine is an indispensable equipment.

3. In order to protect the production environment and the health of the operator, the cutting machine has been equipped with a water tank when leaving the factory, which has the functions of water spray and dust collection.

PU injection machine

1. Accurate ratio and simple operation;

2. Simple structure, easy maintenance and low maintenance cost;

3. With pipeline heating;

4. The equipment is equipped with automatic material lifting function.

5.Mitsubishi made in japan PLC system,

6.Automatic resin refill function:our system are equipped with both delivery pump to refill the resin from the resin barrel to mixer barrel automatic.

Polyurethane pultrusion technology;

Production and manufacture of polyurethane injection and gluing and mould;

Upgrading of existing pultrusion equipment and improvement of technology.

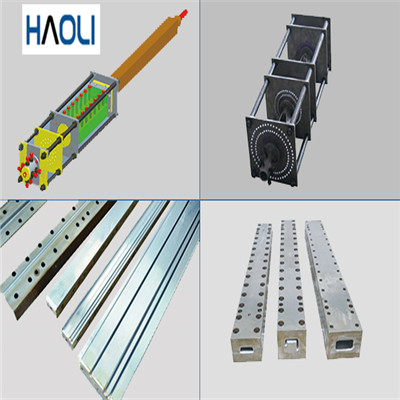

Design and manufacture of pultrusion mold

1. FRP pultrusion die materials are forged from various high-quality die steels;

2. The mold material is subject to tempering, tempering and quenching;

3. Mechanical precision machining;

4. According to the customer's requirements, choose surface chrome plating or surface nitriding treatment, and finally obtain high-precision pultrusion profile mold.

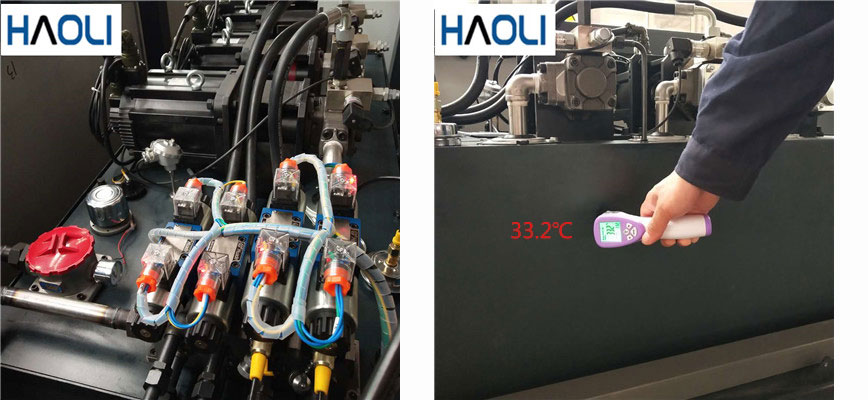

What's the main brand of our hydraulic parts?

● Haoli Pultrusion machinery main choose the high cost-effect parts,but all of parts can be purchased local in

● The pump:We can use the Rexroth type or Yuken type

● The hydraulic pump:Rexroth brand or Yuken brand

● Linear guide:Hiwin Made in Taiwan;

What's the main brand of our electrical parts?

PLC and Touch screen:Siemens or Mitsubish Made in Japan;

ABB and Ormon and Siemens and Schneider

Temperature gauge:ABB or Siements

Control technology:Touch screen with icloud witness where ever you are.

Our Honour!

20 years sepcial made the pultrusion machinery; We are 1st company in the pultrusion machinery to get the ISO 9001 certification since 2001 CE certification; TUV Certification;

Our Service!

We can provide the following services to our customers:

According to the requirements of different pultrusion products, provide the corresponding FRP material pultrusion machine unit and supporting auxiliary machine:

1.Layout design of pultrusion factory and workshop;

2.design of formula, mould and preform and provide technical guidance documents;

3.train technical operators to assist customers to pull out qualified products;

4.our company has pultrusion mould production workshop, which can provide customers with various specifications of moulds.

We can answers the customers' requirement within 24 Hours. If we work aboard,our engineer can go and fix the machinery and do the technology turn-key transfer.

We have professional machining ability

We have professional assembly ability of pultrusion machinery